How Laser Cleaning Technology Is Revolutionizing the Manufacturing Industry

- Rydex Laser

- Jan 28, 2025

- 2 min read

Updated: May 14, 2025

In the ever-evolving landscape of manufacturing, efficiency, precision, and sustainability are paramount. Traditional cleaning methods, such as sandblasting and chemical treatments, have long been staples in the industry. However, these methods often come with drawbacks, including material wear, environmental concerns, and safety hazards. Enter laser cleaning technology — a transformative solution that's reshaping how manufacturers approach surface preparation and maintenance.

🔬 What Is Laser Cleaning?

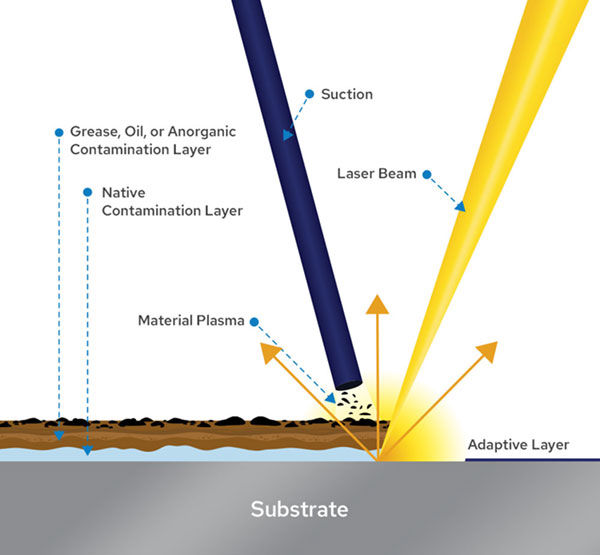

Laser cleaning utilizes high-intensity laser beams to remove contaminants like rust, paint, and oxides from metal surfaces. The process involves directing laser pulses onto a surface, causing contaminants to evaporate or be blown away by the resulting gas and plasma. This non-contact method ensures that the underlying material remains unscathed, preserving the integrity of the workpiece.

⚙️ Precision and Efficiency in Manufacturing

One of the standout features of laser cleaning is its precision. Unlike abrasive methods that can damage delicate components, laser cleaning offers selective removal of contaminants. This is particularly beneficial in industries where intricate parts require meticulous care. Additionally, the speed of laser cleaning can significantly reduce downtime, leading to increased throughput and cost savings .

🌱 Eco-Friendly and Safe

Traditional cleaning methods often involve harsh chemicals and generate waste materials. Laser cleaning, on the other hand, is an environmentally friendly alternative. It eliminates the need for chemical agents and abrasive media, reducing hazardous waste and exposure risks. Moreover, laser cleaning systems are designed to be safe for operators, requiring minimal protective equipment .

🏭 Applications Across Industries

Laser cleaning is versatile and finds applications across various sectors:

Automotive: Removing rust and preparing surfaces for welding or coating.

Aerospace: Cleaning turbine blades and other critical components without compromising structural integrity.

Construction: Restoring steel beams and other materials to their original condition.

Food Processing: Cleaning equipment without the use of detergents or abrasives .

🔧 The Future of Manufacturing Maintenance

As industries continue to prioritize sustainability and efficiency, laser cleaning stands out as a forward-thinking solution. Its ability to provide precise, eco-friendly, and safe cleaning makes it an invaluable tool in modern manufacturing. Companies adopting this technology are not only enhancing their operational efficiency but also contributing to a greener and safer industrial landscape.

For more insights into laser cleaning technology and its applications in various industries, explore the following resources:

By embracing laser cleaning, manufacturers can stay ahead of the curve, ensuring their operations are efficient, sustainable, and poised for the future.

Have questions? Want to see it in action? Contact us today!

Comments